Technical Article

What’s the latest on UL 3741?

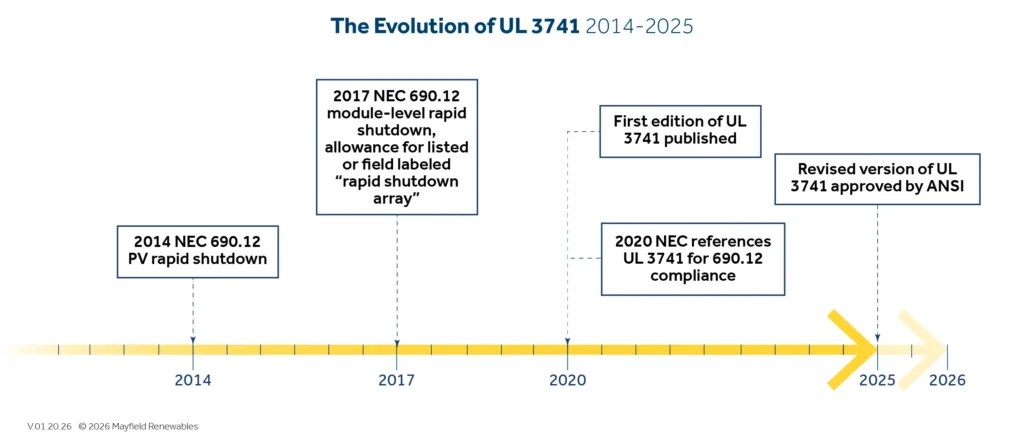

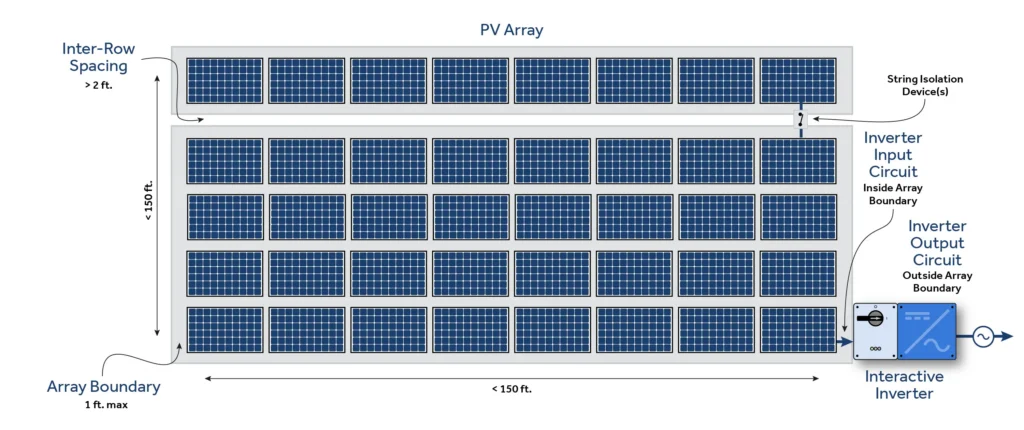

UL 3741 is a safety standard titled Photovoltaic Hazard Control that was first released in 2020 and updated in October 2025. The standard was developed for PV installations required to meet the National Electrical Code (NEC) section 690.12, Rapid Shutdown of PV Systems on Buildings. Installing a PV Hazard Control System (PVHCS) listed to UL 3741 is one method to meet rapid-shutdown requirements for conductors within the array boundary.

We wrote an article on repowering with UL 3741, recently hosted an AMA webinar with guests from IronRidge and Enstall, and we even have a self-paced online course available on the topic. In this article, we’ll review the evolution of NEC rapid shutdown requirements, recent updates to the UL 3741 standard, and related system design trends.

How did we get here?

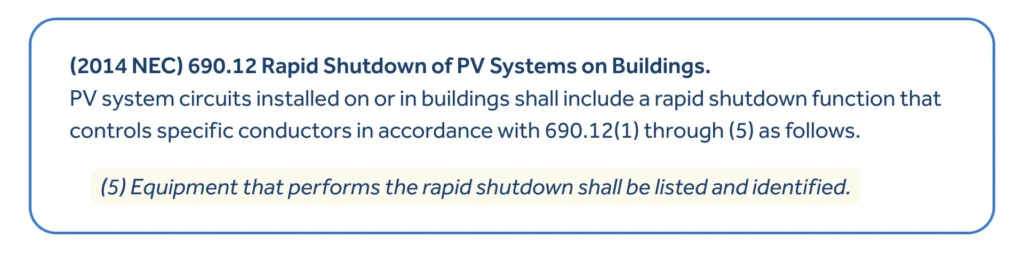

“Rapid shutdown” first entered the solar industry lexicon with the release of the 2014 NEC. The guiding principle behind rapid shutdown requirements is to reduce shock hazards for firefighters who must interact with arrays in emergency situations. In 2020—six years after the 2014 NEC went into effect—UL 3741 was published, introducing a new method for “listed systems” to comply with rapid shutdown requirements.

Section 690.12 in the 2014 NEC introduced requirements to reduce voltages inside and outside the PV array boundary. However, at the time of publication, no “listed” rapid shutdown equipment was on the market.

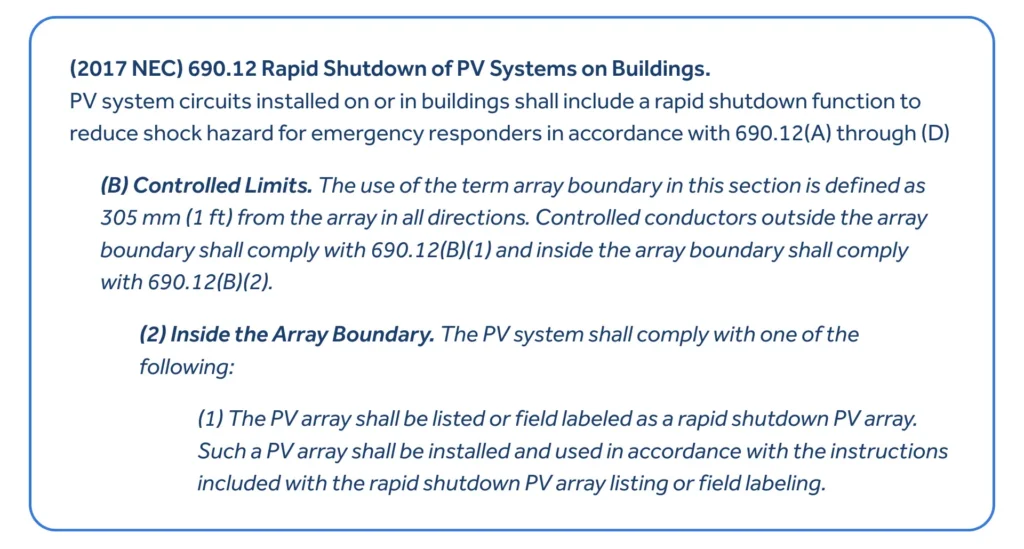

Section 690.12 in the 2017 NEC took a big leap forward with the term “rapid shutdown PV array," further opening the door for a system-level listing which did not exist—yet.

Section 690.12 in the 2020 NEC looked very similar to 2017, but updated the term “rapid shutdown PV array” to “PV hazard control system” to be more accurate (remember: the primary goal of rapid shutdown is to minimize the electrical hazard for first responders) and to better align with the title of the UL 3741 standard which was under development by the time the 2020 NEC was published.

From 2021 onward, the term “PV hazard control system” stuck, and a growing list of manufacturers have achieved UL 3741 listing. The latest update to the UL 3741 standard mostly relates to the listing process, and not to system design. You can find a deep dive into those updates by watching our January 2026 Ask Mayfield Anything webinar with IronRidge and Enstall.

How does UL 3741 impact PV system design?

While exciting in theory, designing an NEC-compliant UL 3741 system can be difficult in certain scenarios. Roughly 20-30% of Mayfield’s commercial projects since 2024 have been designed to meet UL 3741 requirements. We’ve gathered a few key takeaways from our experience, below. If you’re new to UL 3741 designs, check out our primer from 2023 as a starting point.

Contiguous arrays are ideal. The more your rooftop PV system is split into subarrays, the harder it is to ensure that all modules and associated wiring fall into the “PV hazard control array” category. The key to compliance is reducing the shock hazard by controlling power on the conductors and/or protecting them from physical harm. Contiguous arrays create a singular array boundary, thereby simplifying these tasks. For larger commercial projects, in particular, rooftops that allow for single contiguous arrays can be elusive. Most rooftop systems are a collection of fragmented subarrays skirting around vents, skylights, and other roof obstructions.

Fragmented systems may result in some UL 3741-compliant arrays, and some non-compliant arrays that will have to meet NEC 690.12 requirements by other means. It is possible to connect distant subarrays with string isolation devices and other mid-circuit interruptors, but few such products are on the market today. Refer to your racking and inverter manufacturer’s installation guide to identify which components have been evaluated and approved for the application.

Wire management is paramount. This is an evergreen suggestion, really, but much of what determines what constitutes a “PV hazard control array” comes down to workmanship. Inspectors will verify that the array was installed per the manufacturer's instructions. Systems that are listed to UL 3741 will have specific wire management guidelines. As always, read the manual!

Some 3741-compliant systems will utilize module-level power electronics (MLPEs). These systems still require diligent wire management, but the specific requirements may be less stringent than arrays that do not use MLPEs. That said, eliminating MLPE (thereby reducing the total number of connections and failure points) is a major motivator for some designers and installers. And that is the exact approach most racking manufacturers use to complete their listing. Given that these arrays can have open circuit voltages up to 1,000 Vdc, adhering to the installation requirements is the only path to ensuring compliance.

Education, education, education. Change is the only constant in the solar industry. As we’ve seen, codes and standards can sometimes move at a different pace than the engineers, installers, and inspectors who work on these systems. When new design opportunities such as UL 3741 arise, it’s incumbent upon the industry at large to share lessons learned or risk slowing down deployment.

What does that mean in practice? Have conversations with the AHJs who will permit and inspect your projects. Review product manuals with your install crews to ensure they follow wire management guidelines. Take manufacturer trainings whenever offered.

What’s next?

Don’t expect any major updates to NEC rapid shutdown requirements or to the UL 3741 listing requirements in the coming years. Small clarifications, not wholesale changes, are anticipated. Use this time to become familiar with the standard and to educate your network as it becomes more commonplace.

Do expect to see more racking and inverter manufacturers achieve UL 3741 listing under the new listing pathways provided by the most recent update to the standard, and more string- and circuit-level devices hit the market.

Mayfield Renewables is an engineering consultancy specializing in commercial and industrial PV and microgrid engineering. Contact us today for a consultation.