Technical Article

Microgrid Interconnection

Microgrids here, microgrids there, microgrids everywhere—at least that’s how it seems to be in our world these days. The number of considerations for a successful microgrid is staggering, from feasibility through construction. On the engineering and technical side, we have several codes and standards to adhere to while juggling utility, local inspectors, and owner expectations and restrictions. On the financial side, the system's lifetime operation has to be accounted for to ensure that everything pencils out.

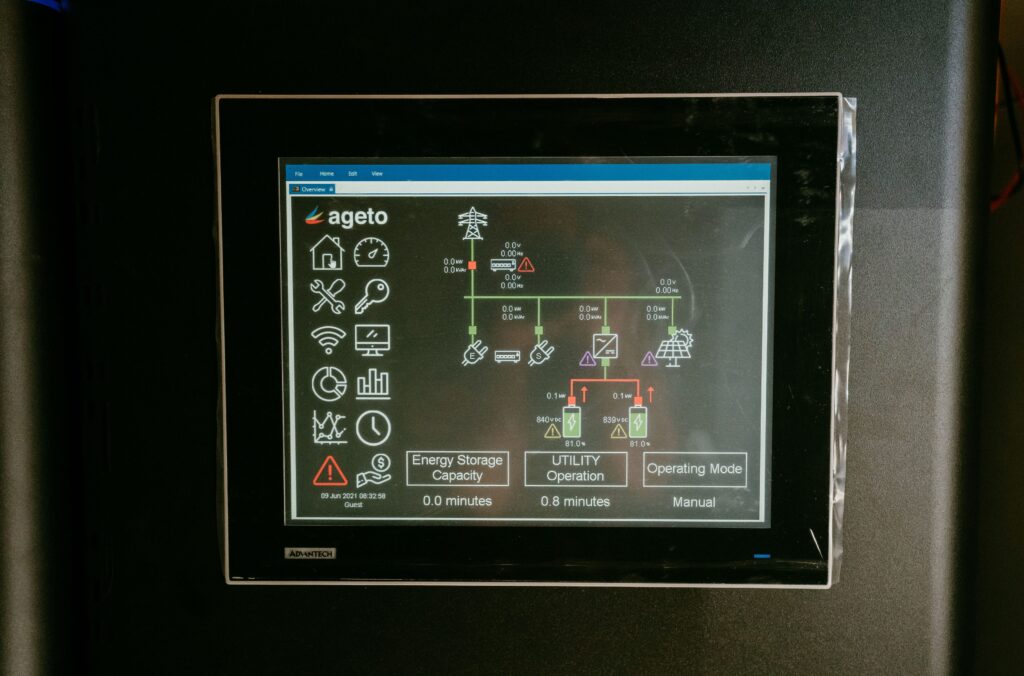

One key detail we have found that can considerably impact a project is the interconnection of the energy storage system (ESS) with the electrical service from the utility, specifically the method by which the microgrid isolates from and connects to the utility. Unlike grid-direct PV systems, where the PV inverters can meet the utility requirements for isolation from the grid with standard features, isolating a microgrid from the utility can be a complex process.

It is worth noting that the complications noted here are specific to ESSs that can operate in island mode, backing up on-site loads while disconnected from the grid. Not all ESSs have this functionality; therefore, non-backup systems tend to have fewer interconnection complications.

Microgrid Interconnection Devices (MIDs)

Interconnecting microgrid systems to the utility requires significant thought and planning for a successful project. The biggest hurdles we have seen as the engineer of record commonly occur with the interconnection agreement with utilities. Utilities see plenty of microgrids where an engine generator is on the customer side of the system, and transfer switches (either automatic or manual) are employed to ensure the generator's isolation from the utility system. These transfer switches are reliable isolation methods and easily integrated into such a system.

Inverter-based systems that meet the UL 1741 requirements for grid isolation are also standard for utilities. Some ESSs use such inverters with integrated microgrid interconnect devices (MIDs), which help minimize the complications associated with utility interconnection.

We add complexity to the utility interaction when introducing ESSs without integrated MIDs into this equation. This type of ESS is common in commercial applications.

Transfer Switches

You may be asking, “why not use a tried-and-true transfer switch to isolate the ESS from the utility?” Typically, we want the ESS and any associated PV system to see and connect with the utility to provide grid services when the utility is present, allowing the PV + ESS system to send power to the grid. Therefore, using a transfer switch and connecting the PV and ESS to the terminal that would typically house the generator would eliminate the possibility for the PV + ESS system to provide power to the utility. Other difficulties can also arise, so generally speaking, a transfer switch isn’t a good solution for providing the interconnection point for an ESS to the utility.

Contactor Isolation

A popular solution is to include relay-based protection, which uses protective relays to control a contactor and achieve utility isolation. Contactor isolation is one of the most common solutions we present to our clients. Typically, utilities are familiar with and confident in the protective relays and their ability to isolate the ESS from the utility. The relays are programmable to evaluate several utility conditions, such as over- and under-voltage, frequency, and fault conditions. The relays are programmed to predefined IEEE values that provide the utilities with the proper protection for the grid.

The specific location of the contactor can vary from one system to the next. If the ESS provides whole-building backup, the contactor will likely be required between the main service disconnect and the main service panel. This arrangement can add a high complexity and cost, especially in existing electrical panels.

If the microgrid provides backup for a subset of the building’s loads, locating the contactor downstream in the electrical system will be an acceptable solution. This can be less complex because of the ability to integrate the required MID after the main service panel. In addition, the current values of such systems are likely to be lower and don’t require high-amperage components.

Motorized Breakers

Another solution for the microgrid interconnection is the use of a motorized breaker. As the name implies, these breakers include a motor that allows them to receive a signal from a protective relay controller to open (turn off) and close (turn on). Motorized breakers can be integrated into certain main service panels, providing overcurrent protection and disconnecting means. This option can be straightforward to implement when the electrical gear is compatible.

As with all systems that integrate to and operate in parallel with the local utility, contractors need to secure an approved utility interconnection agreement. Given the complexities and newness of microgids in general, we have seen utility requirements can vary dramatically. We advise approaching your utility with a proposed solution that is feasible for the site and is standard practice within the industry. Sometimes, getting on a call with the local utility engineers to walk through the system configuration and operation is helpful for the approval process.

The interconnection of your microgrid to the utility can be a straightforward process to a complex engineering solution that requires multiple vendors and approvals. We will cover this and several other microgrid-specific topics at our annual Education Summit in Seattle, WA, on October 15th and 16th.