Technical Article

How ASCE 7-22 Updates Will Impact PV Racking Systems

When an engineering standard changes, its impacts spread far and wide. Future code cycles will integrate the new standard; AHJs will adopt those codes for permitting and inspection; and manufacturers will adjust their products to meet the new code requirements.

One example of this phenomenon was the introduction of rapid shutdown requirements in NEC 2014, which quickly changed how rooftop PV systems were designed, built, and permitted. The module-level power electronics market boomed as a result.

In this article, we’ll look at consequential provisions of the engineering standard ASCE 7-22, Minimum Design Loads for Buildings and Other Structures, which is already adopted in Florida and will be referenced in the 2024 IBC and IRC. We’ll review the important updates from ASCE 7-16 (2016) to ASCE-22 (2022) and their impacts on PV designers and PV racking manufacturers.

What is ASCE 7?

The American Society of Civil Engineers (ASCE) is the oldest national engineering society in the United States. Since the 1850s, ASCE has developed over 70 engineering standards and disseminated countless technical journals. Many AHJs rely on ASCE guidelines for permitting. I-Codes such as the IBC, IRC, and IFC will often reference ASCE standards as the basis for Code requirements.

One such standard is ASCE 7, Minimum Design Loads for Buildings and Other Structures, which provides requirements for live, dead, wind, snow, seismic, soil, flood, rain, and ice loads. The first edition of ASCE 7 was published in 1988 and gets updated roughly every six years. Until the 2016 edition (ASCE 7-16), PV systems were not mentioned. The 2022 edition (ASCE 7-22) builds off of ASCE 7-16 and introduces many new solar-specific requirements.

ASCE 7-22 will be a reference standard in the 2024 IBC and IRC, which many states are expected to adopt as soon as next year. As of this writing, Florida is the only U.S. state to already enforce the ASCE 7-22 standard (in tandem with the 2021 IBC). You can use resources like UpCodes or Code Check to check when your state plans to adopt the 2024 IBC or IRC.

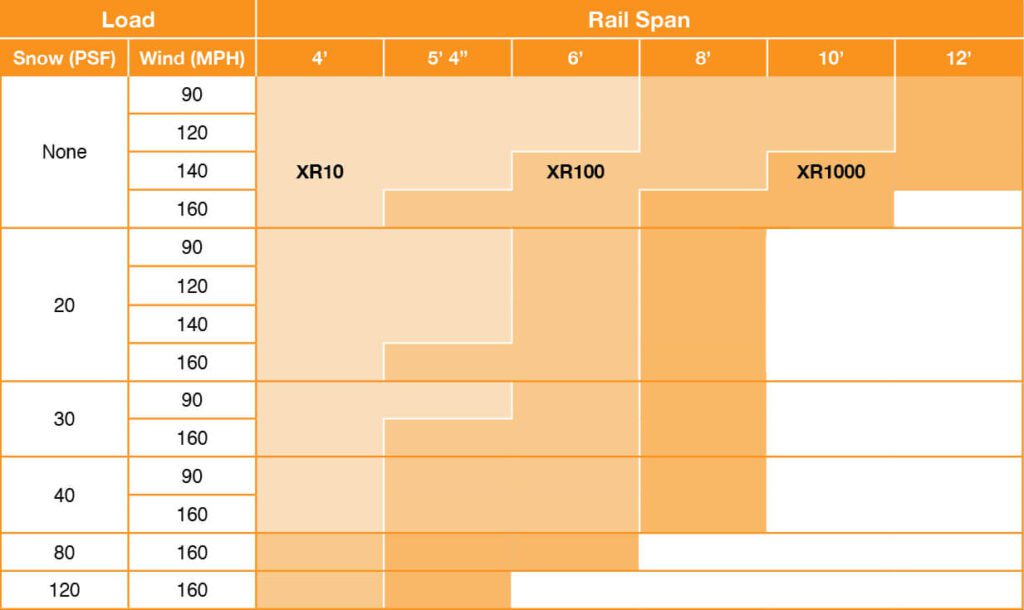

The onus falls on racking manufacturers and structural engineers of record to prove compliance with the ASCE 7-16 or 7-22 standard and any associated Code requirements. This is accomplished through lab tests and certification letters, which will often include allowable span tables for system design.

What has changed since ASCE 7-16?

ASCE 7-16 introduced solar-specific provisions—for flush- or tilt-mounted rooftop PV systems only—including new roof zones, roof types, wind and seismic load requirements, pressure coefficients, and a whole host of other changes from ASCE 7-10.

The 2018 and 2021 IBC, IRC, and IFC adopted ASCE 7-16 as a reference standard for loads, so it’s currently enforced by most AHJs around the U.S. Since ASCE 7-16 is already widely adopted, we’re going to focus on the biggest changes in ASCE 7-22. We’ve bucketed notable updates into three main categories: wind, snow, and seismic.

Wind Provisions

Wind load provisions and wind tunnel test procedures are outlined in ASCE 7-22 Chapters 26 through 31. Within the first few words, Section 26.1.1 introduces a new requirement that structures in Risk Category III or IV must be designed to resist tornado loads per Chapter 32:

“Risk Category III and IV buildings and other structures, including the MWFRS and all C&C thereof, shall also be designed and constructed to resist tornado loads determined in accordance with Chapter 32, as applicable.”

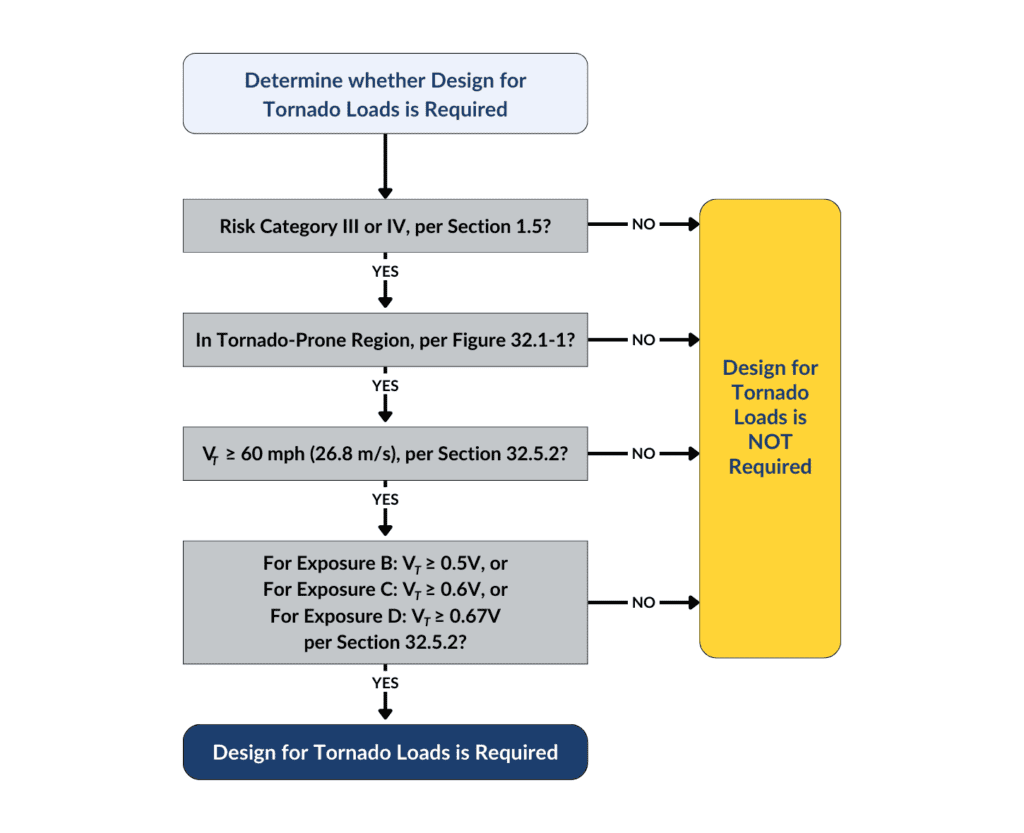

Skipping ahead to Chapter 32, we see a helpful flow chart to determine when tornado loads must be considered. Note that Table 1.5-1 defines Risk Categories by building use or occupancy, and Figure 32.1-1 shows tornado-prone regions in the U.S. A school or hospital in Kansas, as an example, would meet the qualifications for steps 1, 2, and 3 below.

Looking back to Chapter 26, you’ll see small updates to topographic factor criteria, velocity pressure coefficients, and the velocity pressure equation, but no new requirements that are specific to PV systems. The next big changes are in Chapter 29, which introduces new methods for calculating wind loads for fixed-tilt ground-mount systems (Section 29.4.5) beyond the provisions for flush- or tilt-mounted rooftop PV systems established in ASCE 7-16. Simplified Figures in Chapter 30 also reduce the number of roof zone designations.

The new wind provisions will force PV racking manufacturers to expand their wind tunnel studies for fixed-tilt ground-mount systems and to test for tornado loads. Wind tunnel testing is described in a separate standard, ASCE 49.

Snow Provisions

The methodology for estimating snow loads underwent a significant change from 2016 to 2022. Thanks to improvements in computational power and access to 40 years of additional snow load data, ASCE 7-22 ground snow load maps are much more granular than their predecessors and reduce the number of case study regions by 90%. Another consequence of the new methodology is that expected snow loads increased greatly in many regions of the U.S. This is most pronounced in regions that have a large relative difference between the typical annual maximum load and the extreme annual maximum load.

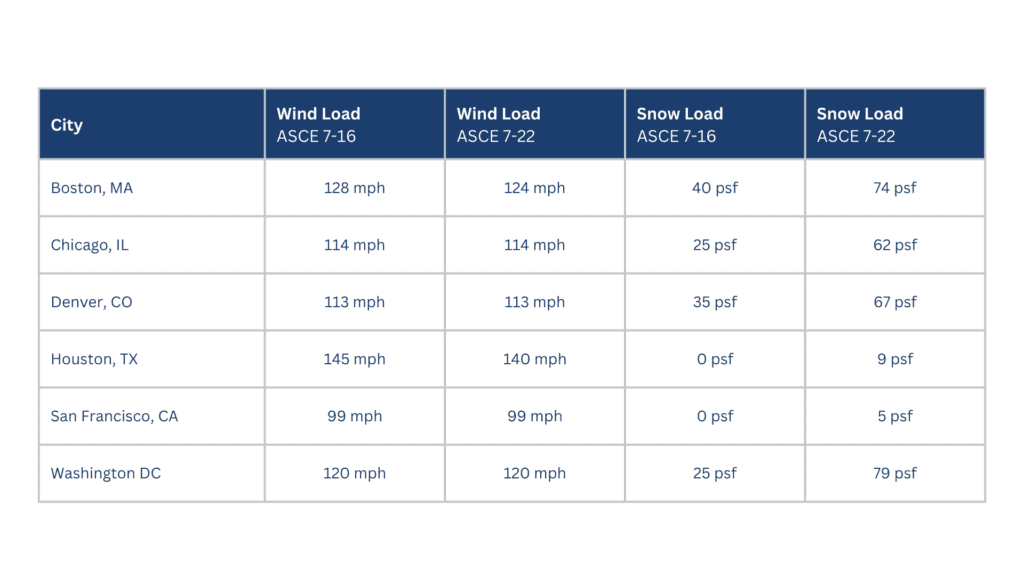

The free ASCE Hazard Tool shows estimated wind, snow, ice, and other loads when given a street address or coordinates. Users can also toggle between ASCE 7-16 and 7-22-based calculations. The table below shows snow and wind loads for major metropolitan areas across the U.S.

Note that wind loads saw a slight decrease on average while snow loads for all locations increased. Section 2.4.1 includes a new load combination of D + 0.7S (dead load plus 0.7 times snow load) for allowable stress design. This allows for a lower design load, but not all the way back to ASCE 7-16 levels.

The implications of increased snow loads are most notable for rooftop racking manufacturers, who will have to update their span tables and technical documentation. Installers who are accustomed to using thinner, lighter rail to cut costs may need to pivot to sturdier options designed for heavier snow loads.

Seismic Provisions

Last but certainly not least, new seismic loading provisions in Chapter 13 will change how ballast systems are designed. Tucked into the exception to Section 13.6.12 is the line:

“solar panels shall not be considered as part of the load path that resists the interconnection force unless the panels have been evaluated or tested for such loading”

In other words, a PV module cannot form the bridge between two isolated mountings in ballasted, unanchored systems. We cannot assume a module will act as a load path between ballast trays unless it has been tested to do so. Many ballast systems on the market today would not comply with this new ASCE 7-22 exception.

Historically, module manufacturers have been required to perform uplift and downforce tests but not tension-compression tests. That burden has fallen on racking manufacturers, which now have a few paths forward:

- Update ballast products to interconnect through a grid-based racking system that connects the components together through hardware rather than using modules to transfer and carry the structural loads.

- Perform seismic load-path tests on fully constructed ballast systems with specific modules to generate a list of approval letters.

Neither option is especially appealing or affordable. Product R&D is slow and expensive, but a more permanent solution. Lab testing will verify compliance but will also constrict design options to a finite list of compatible, pre-tested modules.

Luckily, there’s time to adapt to all the changes in ASCE 7-22. Florida is the first and only state to follow ASCE 7-22 as of this writing. Other states and AHJs will follow suit once the 2024 IBC and IRC are adopted. Racking manufacturers who get ahead of this new standard—and its downstream impacts on Code—will be setup for success in 2025 and beyond.

For more information on the latest PV racking standards, register for our upcoming Ask Mayfield Anything on Structural Criteria Updates for Rooftop PV: ASCE 7-22 and ASTM 1761.